MPI Services

Free Estimates | ISO Certified Business | Quality Workmanship

Free Estimates

ISO Certified Business

Quality Workmanship

Reliable Detection of Surface and Sub-Surface Indications

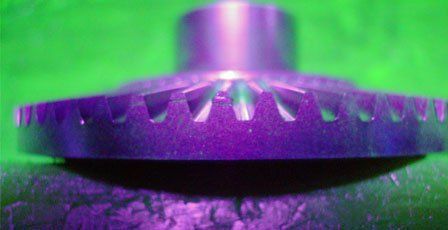

Our semi-automated MPI units are capable of single- and multi-directional shots to detect surface and sub-surface indications. To meet your requirements, we have water and oil mediums available and use black light inspection.

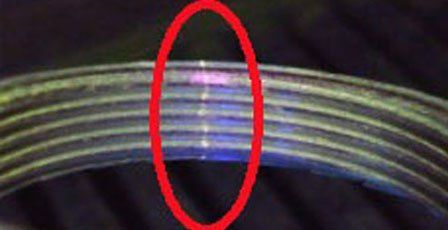

Magnetic particle inspection is a great method of crack detection. After a part is magnetized, fine iron particles coated with a dye pigment, bridge or arc the crack. This helps us detect if there is a problem with your shipment.

Call Arete QIS today with your MPI inquiries today. Same-day services are available for an additional fee. You can also request an estimate by filling out our short form.

Comprehensive Services, Reliable Results

Did you know that Arete QIS is a leading ISO 9001:2015 certified industrial solution provider? Our company was formed with the idea of meeting all of your sorting, inspection, packaging, and special manufacturing needs. We provide innovative services throughout the USA and Europe.

Explore our other services such as tumbling, inspections, ultrasonic cleaning, and electronic component mechanisms. Call (814) 781-1194 and let us know how we can assist you.

Magnetic Particle Inspections

Magnetic particle inspection (MPI) is a form of non-destructive testing that uses magnetism and specially designed particles to detect indications of cracks. Compared to some other methods of non-destructive testing, MPI is a faster and more efficient method of testing for cracks. Arete uses the wet-fluorescent method of MPI with fluorescent particles and black light inspection.

Here at Arete, our machines are capable of single and multidirectional shots to provide the most specific inspections required. Our machines are able to run as AC or DC to detect surface and sub-surface indications. We offer both water and oil solutions to suit the needs of our customers. The particles used in the water and oil baths vary in size to provide the best possible results for a range of crack widths. Our water solution contains a liquid concentrate that includes a rust inhibitor to protect parts with no additional processes required. No rust preventative steps need to be taken with our oil bath.

Arete has two inspection rooms equipped with overhead black lights for optimum inspection. After sorting, all parts are demagnetized according to specific requirements. From here, the options are open to customer needs. Parts can be packed directly at the MPI area or sent to our sorting department for special packaging or further inspection.

The operators in our MPI department have specific training for MPI. All inspectors are certified at a minimum of Level I-Limited before being trained on inspection. Training courses are held intermittently for Level I and Level II technician certification according to SNT-TC-1A and NAS-410. These courses are conducted by our Level III consultant. Our MPI department is overseen by a supervising Level II technician.

The quality and procedures of our MPI department are handled by Georgia Cornell, a Level II consultant. Georgia has worked at Arete since June 2010 and was certified a Level II technician in October 2010. In December 2011, she began handling MPI quality matters and procedure set-ups and overseeing the training and evaluations of MPI operators. In addition to MPI, she is currently studying other NDT methods in order to obtain a Level III certification.

Magnetic Particle Inspection is the Future of Manufacturing

Call us today for a FREE estimate.

(814) 781-1194

Share On: